New generation anchors, such as the Spade and Rocna, consistently out-perform the older CQRs and Bruces, and owners of these upstart types without exception swear to the marked improvements they bring to the stressful task of anchoring. However, a schism exists between these more open-minded boaters and those who value the ‘tried and true’ and the traditional; and who, despite the bemusement of the early adopters of what is clearly far superior technology, continue to use designs that in the case of the CQR is (without hyperbole) rather akin to the use of cotton sails and oil lanterns.

Arguments from proponents of old generation anchors, and detractors of the new, commonly reduce to they’ve always worked so why change? Apart from betraying an obvious lack of perspective on the concept of progress (should we all be using no technology developed later than 1933?), these complaints seem to present a point difficult to rebut. Boats whose owners insist on keeping the CQR in service clearly do not always spontaneously drag once their anchor is deployed and the skipper looks the other way. What then, is really the problem with these old generation types?

The old generation designs

The truly old generation anchors are those which even the most die-hard CQR adherent would not term “modern”: their origins in the murky past well before the 20th century, typically now not even recognized as being small boat anchors at all. The Fisherman and Admiralty patterns occupy a unique place in the nautical annals of the world – however, they are now mostly relegated to that history and have little or no place onboard a modern small boat. (“Small boat” refers to any vessel using a primary anchor much under 200–300 kg. Ships above this size begin to require certain characteristics of their anchors, such as a symmetrical nature, and are outside the scope of this article).

“Old generation” is the label now attached to those anchor types and designs dating before the Bügel (1986) and Delta (1990). The Bügel features some new generation design concepts, while the Delta is fundamentally a plow, so these two types define a bit of an overlap between the ‘old’ and ‘new’ generations.

The CQR (articulated plow)

Origins and modern day status

Developed in the early 1930's by British mathematician Geoffrey Ingram Taylor, the CQR is an articulating plow, distinguishing it from the improved fixed-shank variant of 60 years later (i.e. the Delta). The articulation has nothing to do with allowing the rode to veer without disturbing the fluke; rather, it was necessary to get the anchor to set, by angling the fluke tip to the seabed correctly. This works only partially and the hinge is a headache, creating wear issues and injuring many a boater’s fingers – a problem not solved until the Delta. For asymmetrical anchors to set, reliable self-righting is required to prevent the anchor from lying upside-down, and the CQR represents the first attempt at solving this problem. Had Taylor taken his concept further, he almost certainly would have progressed it to something similar to the Delta.

The genuine CQR brand is now owned by Lewmar, having been traded a number of times in its lifetime. Of course the design is out of patent and poor copies abound, most of even worse performance and questionable construction quality. Unfortunately their popularity is assisted by the relatively high cost of the genuine CQR.

“I’ve used most types of anchor – CQR, Bruce, Danforth, Fisherman etc… I was most frustrated with the CQR, even though ours was oversize for the boat. In the hard, fine sand of the Isles of Scilly I came the closest I have ever come to losing a boat, when our CQR dragged in 60 knot gusts. Many, many times I cursed the thing when trying to get it to bite in any anchorage where there was weed present.

“So when the new generation of anchors came along I was ready to give one a try, and plumped for the Rocna… and I have to say it has proved (over the last two seasons) worth every penny. Not only does it set instantly like a car’s handbrake and hold like a rock, but, remarkably it does so in such a wide variety of substrates. It really is the best piece of kit I’ve bought in recent years.

“British yachties are very conservative - most of them will not hear a word against the good old CQR. But… most people who sail “outside the box” a little wouldn’t have a CQR as a main anchor these days, any more than they would want to fly across the Atlantic in a biplane. I am convinced of one thing – anyone who ever tries one of the new generation of anchors will not be going back to their old CQR in a hurry.”

— Colin Speedie, writing on Attainable Adventure Cruising

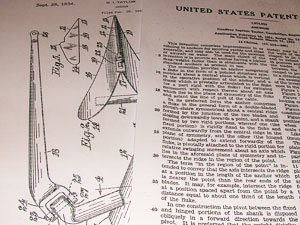

The CQR patent, filed in the US in 1934, offers an insight into the concepts of its inventor, and a foil to some myths floating around the boating community…

…as does a short article published the same year by Taylor in The Yachting Monthly and Motor Boating Magazine:

Performance of the CQR and plows in the 21st century

It cannot be denied that the CQR gifted to boaters a large improvement over the antiquated alternatives available in the early 20th century; it was the world’s first “small boat anchor”, an asymmetrical design with all the associated efficiencies of performance. In the 50 years following its beginnings, it enjoyed a near monopoly on the small boat market, while that market remained small and exclusive. This established it with a strong legacy and a status in the minds of many boaters as the anchor of choice. Tradition and lore in the nautical world are powerful endorsers. However, there has been much work and development on anchors since, and the performance of plows compared to the all-round excellence of new generation types is really quite miserable – much like, of course, many other products dating from the 1930's compared to their eventual replacements.

From a modern perspective, performance issues with the CQR are evident in all metrics which define a good all-round anchor, including inconsistent setting performance (commonly not setting at all), poor holding in soft bottoms, and failure to penetrate in hard ground. The fluke shape, unsurprisingly perhaps as it is a plow, is inherently designed to furrow, not to hold. This was used for the CQR at the time as it was not clear how to make a different geometry set reliably – a planar or concave fluke design would not work with the articulating shank concept. The CQR does not tolerate weed or grass well, and generally has few redeeming features.

This characteristic of inconsistent setting leads to unpredictable anchoring. Anchors must be in a particular attitude in order to set, and slight flaws in the design of the anchor lead to the attainment of this attitude being a hit-and-miss affair. If an articulating plow lands with its blade in an upright position, it will usually set without problems, but if the fluke (the actual plow part) lands on its side, with the shank rotated away, a bite on the seabed may elude it completely. Especially on a hard bottom, it is not uncommon to drag a plow in this situation for 50 meters without a set. Moreover, this has obvious implications for an unattended anchor which is pulled out (perhaps during a wind veer) and is being relied upon to automatically re-set.

Proponents of the CQR have a tendency to dismiss these issues, if they are even aware of them, as problems to be overcome by ‘skill’ or ‘experience’, as if the anchor is an element of the vessel to be controlled no differently to the helm, sheets on a sailboat, or trim-tabs on a powerboat. Talk abounds of the ‘proper technique’ by which to set an anchor, in the hunt for the mythical formula of process that will bring anchoring success. The reality is that, beyond some basic best practices, anchoring should not be like this. Moreover, as touched on above, the anchor is clearly not permanently under control or supervision once deployed; how many yachts maintain a permanent anchor watch? A boat’s anchor, pulled loose at 3 am, does not care for the ideas on anchoring technique of the sailor fast asleep in his bunk.

The CQR was tested and developed by Taylor primarily in the forgiving English anchoring grounds of Essex and Suffolk, which present an environment of almost entirely soft mud and sand. It is possible that Taylor never witnessed his design in any attempt to use it in more faraway anchorages. Cruisers these days tend to demand an anchor capable of handling less gentle environments. It is perhaps a result of this that despite the CQR’s respected place in history, the plow is not to be recommended as a general purpose anchor and has no place on a modern yacht.

Compared to the new

The following summary comments (complete and verbatim) from West Marine relating to their 2006 anchor comparison testing are referred to in order to exemplify the differences between the CQR and the Rocna:

- CQR 35 (38.5 lb):

“One promising set to 2,000lb., but little else. Would not engage bottom.”

- Rocna 15 (32 lb):

“Superb, consistent performance. Held a minimum of 4,500lb and engaged immediately.”

The following efficiency ratings (holding capacity vs measured mass) from John Knox’s test published by Practical Boat Owner in August 2011 reiterate the truly drastic differences that are apparent in controlled testing:

- CQR 45 (47 lb):

- 8

- Rocna 15 (35.7 lb):

- 30

Finally, the CQR, and many articulated plow copies, are classified as HHP (High Holding Power) by one or other of the classification societies (Lloyd’s, RINA, et al). The Rocna is classified as SHHP (Super HHP), a higher standard which requires the anchor to resist pulls at least 200% that of a HHP anchor, over three different seabeds.

The Danforth type

Origins and modern day status

The Danforth, a twin-fluke symmetrical anchor, has strong affiliations with anchors of antiquity, particularly un-ballasted stockless types. The flukes of these anchors ‘flop’ either side of the shank with the result that the anchor is functional regardless of which side happens to land on the seabed. The flat plate of the flukes, built from steel and able to achieve a strength and durability unavailable in the past to engineers working with cast iron, allow a large surface area for minimal weight. It was developed a little after the CQR by American Richard Danforth, with a number of patents filed for various iterations of the design throughout that period. The recognizable current form was put on paper with the US Patent Office in 1948.

Genuine Danforth anchors are now manufactured in Atlanta, Georgia, by Tie Down Engineering. The Danforth name, while a trademark, is fairly genericized and many imitations are incorrectly referred to and even retailed as Danforths.

“The closest I’ve come to disaster was when my anchor dragged over a mile across a bay, towards rocks and a wall of concrete at Seaview, Isle of Wight. It was 0300 and everyone aboard was asleep when a windshift, aided and abetted by a change of tide, caused the Fortress anchor to break out and drag… Though renowned for superb holding power, Danforth types can break out if the pull changes direction and they don’t always regain their grip…”

— Editor’s Log, Yachting Monthly December 2006

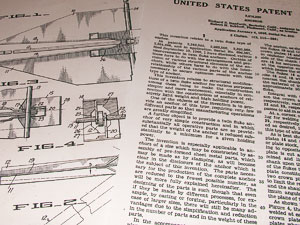

Richard Danforth’s 1948 patent provides a perspective on the immature field of small boat anchors at the time of its development.

Performance of the Danforth and variants in the 21st century

The Danforth type’s primary distinguishing characteristic is found in its large flat plate flukes, which offer a large surface area relative to the weight of the anchor. When set, this translates to a high holding power, well in excess of the CQR, its only small boat competitor at the time of its development. Early Danforth types were using during the war to winch landing craft off beaches – certainly the superior choice at the time for such a task. The Danforth still offers good performance by this simple measure: its problems lie elsewhere.

The Danforth is in essence an improved version of the 19th century Admiralty pattern and stockless variations thereupon. Superior steels and economical access to them permitted radical changes to the age-old designs, but the Danforth does not represent a clean break away from these types. It offers better holding power, and attempts to dampen the rotating impulse (which results from the presence of more than one fluke) by employment of several tricks including the retainment of a dedicated stock (located in front of the flukes rather than at the end of the shank). However, rooted in its past as a symmetrical anchor, it still suffers from a number of setting and behavioral issues. Because the flukes lie flat on the seabed before setting, the process of encouraging it to set depends on the tip of a fluke achieving an initial ‘bite’ – and on hard sand or grassy seabeds, this is not a given. It can skate along the surface without setting at all. This initial setting issue then implies other problems later.

Some manufacturers of the type even admit to this problem, advising users to set the anchor at a very short scope in order to lift the shank and thus exert a vertical pull on the crown of the anchor, the hope being that the flukes will then be angled downward. This tacit admission that the anchor will not set reliably at sensible scopes must inform its consideration as a general purpose anchor required to handle wind veers, changing depths with tides, and the myriad of other real world ramifications.

The Danforth types’ behavioral problems include an inability to reliably handle force veers. Rather than remain buried when a sideways or reversed pull is applied, they tend to twist and pull out. Similarly, if the anchor is dragged once set (e.g. in soft mud), it has a strong tendency to trip on one fluke or the other, rolling and again popping out. Once this has happened, the anchor is unlikely to re-set itself.

There are a number of other issues, including a reduced strength and durability. Even with good quality construction and high tensile steels or aluminium alloys, the geometry of the design does not lend itself to a rugged build. The flukes are flat plates with little reinforcement possible, and the tips are easily damaged. Furthermore, if the force on the anchor is unbalanced, e.g. if one fluke gets stuck but not the other, it is very easily bent and destroyed. Finally, the aforementioned issue with accepting changes in the direction of pull has consequences should the anchor be very well set in hard ground such as clay. The large flukes may be sufficiently well stuck that the shank bends before the anchor will re-align itself, a common mode of failure. Such a fragile anchor so vulnerable to destruction in the course of normal usage has little to commend it to the role of a vessel’s primary anchor.

Because the Danforth types are flat, they tend to be easily stowed, and are therefore popular secondary anchors. Additionally, they do without doubt hold well in simple circumstances, and so are reasonable solutions for secondary anchors (to be used where the anchor may be set once and not expected to handle more than a unidirectional pull). Nonetheless, there are other modern solutions which are superior for this purpose and avoid the drawbacks, including the Spade which has a demountable shank and is also available in aluminium – indeed the alloy version has been independently tested to out-perform the best aluminium Danforths on a weight-for-weight basis.

Compared to the new

The following summary comments (complete and verbatim) from West Marine relating to their 2006 anchor comparison testing are referred to in order to exemplify the differences between the a generic Danforth type and the Rocna:

- West Marine Performance 20 (26.3 lb):

“Disappointing results considering previous tests. Held 200 to 1,500lb, but could not get a secure grip.”

- Rocna 15 (32 lb):

“Superb, consistent performance. Held a minimum of 4,500lb and engaged immediately.”

The Bruce (claw)

“Much of their popularity derives from the ease with which they stow on the stemhead. But their performance proved disappointing… In gravel these claws bounce about whereas in sand they lie down on their side and rarely exceed 200 kgf of holding power.”

— Antoine Sézérat, Voiles et Voiliers December 2003

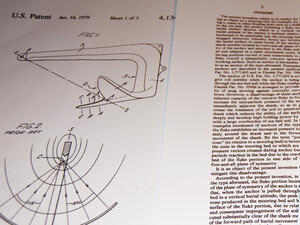

The Bruce patent, filed in the USA in 1976

Origins and modern day status

Peter Bruce launched his new anchor design to great interest from the boating community in the early 1970's, the UK patent having been filed in 1971. The anchor features a triple fluke configuration which forms a ‘claw’ shape. It enjoyed a good level of success, addressing many of the problems, mostly those pertaining to setting reliability, of the CQR and Danforth, then the only alternatives for small boats. This success was perhaps its downfall when the intellectual property protection expired, as it quickly became one of the most imitated types. The design is cast as a single piece, lending it to inferior production processes which undercut the high quality heat treated casting used originally by Bruce Anchor Co. Today, the genuine Bruce is no longer produced, and only poor quality copies remain available.

Performance of the claw type in the 21st century

Claw types, despite the initial success of the original Bruce, do not perform particularly well in terms of holding power. They are therefore inefficient, requiring a heavier anchor to achieve the same holding ability as even a plow. Even proponents of the type tend to accept this trade-off.

The anchor’s benefits instead supposedly lie in setting reliability, and when compared to plows and Danforth types it is true that claws generally perform better across a somewhat wider range of seabeds. However, this comparison is not particularly useful in light of the new generation of anchors now available, and the claw does have a number of serious flaws when examined from a wider perspective. One of these was described by a magazine tester as “hop and skip” behavior, referring to the unstable nature of the claw when pulled beyond yield (dragged). It tends to rotate then pop out violently in a manner not dissimilar to symmetrical anchors with multiple flukes.

The claw also has three separate flukes, all fairly blunt, which do not cut and penetrate weed or grass very well. This also affects its setting performance in hard sand and clay. The configuration of the flukes tends to act as a trap for rocks and boulders, and other undersea obstacles, giving the design a poor reputation for fouling itself on these things.

Moreover, the claw does not set particularly well in harder seabeds if the anchor lands upside-down. In this position it relies upon one of the side flukes ‘grabbing’ the ground in order to trip the anchor into the correct attitude. This is not guaranteed to happen, and some copies in particular are quite capable of remaining on their back and skating along indefinitely.

While the claw was the anchor of choice for well known sailors and cruisers for many years, the death of the genuine Bruce combined with the progression of technology has seen many of these boaters adopt new generation anchors instead. Cruising guru couples Steve and Linda Dashew (SetSail), and Evans Starzinger and Beth Leonard, used to have Bruces on their bows, and are now using Rocnas.

Compared to the new

The following summary comments (complete and verbatim) from West Marine relating to their 2006 anchor comparison testing are referred to in order to exemplify the differences between the a claw type and the Rocna:

- Claw 33 (36.3 lb):

“Failed to set during this test. Maximum tension under 700lb., briefly.”

- Rocna 15 (32 lb):

“Superb, consistent performance. Held a minimum of 4,500lb and engaged immediately.”

The following efficiency ratings (holding capacity vs measured mass) from John Knox’s test published by Practical Boat Owner in August 2011 reiterate the truly drastic differences that are apparent in controlled testing:

- Bruce 15 kg (35.5 lb):

- 5

- Rocna 15 (35.7 lb):

- 30

Finally, many claws are classified as HHP (High Holding Power) by one or other of the classification societies (Lloyd’s, RINA, et al). The Rocna is classified as SHHP (Super HHP), a higher standard which requires the anchor to resist pulls at least 200% that of a HHP anchor, over three different seabeds.

The Delta (fixed-shank plow)

The Delta is a fixed-shank plow, essentially a development of the CQR as described above, and a substantial improvement over that early articulating version of the type. Peter used one for many years including his semi-circumnavigation from the UK to New Zealand. However, its flaws, made obvious in certain locations on that trip, were partly the incentive behind development of the Rocna design: while the Delta was the best anchor in the early 90's at the time Peter’s yacht was outfitted, there remained much room for improvement.

“Maerin was equipped with a Delta Quickset 45 as primary… The Delta’s name belies its capability, although it may set quick, it’s very easy to drag it around in a blow. My experience is that it’s difficult to set, doesn’t stay set… We’ve used the Rocna extensively… It has performed superbly… I really love [it], it’s improved our rest on board, and has really improved our confidence in anchoring …sets quickly, and securely. Best $1400 of insurance I ever bought!”

— Steve Sipe, MV Maerin USA

“Switching to the Rocna took some adjustment for me. It sets quickly, so I had to calibrate where I expected the anchor to set differently (we had a Delta 88 lb prior to the Rocna). I have also noticed more work is required to raise the anchor (snug up the chain, pull the boat forward slightly to break the anchor loose, then raise). I am very pleased with the Rocna.”

— Steve Hogan, SV Robin Ann USA

Origins and modern day status

The Delta was developed in the 1980's for commercialization by British marine manufacturer Simpson-Lawrence. It is a fixed-shank plow; the need for articulation as used for the CQR was avoided with more careful balancing of the anchor’s weight and shaping of the rear end of the fluke in order to permit self-righting and better guide the anchor through the setting process. The basic shape of the fluke nonetheless remains a plowshare, with a brake-pressed plate heel and solid steel cast tip (welded together to form the only joint attaching the tip to the rest of the anchor). This design necessarily relies on tip-weight for ballast and setting, an inefficiency which detracts from fluke surface area and ultimate holding power.

The genuine Delta brand is now owned by Lewmar. The anchor has been out of patent for a few years now, and poor copies abound, most of worse performance and questionable construction quality. The Delta, by no means perfectly engineered, was properly tested and uses quality steels to attain the required strengths.

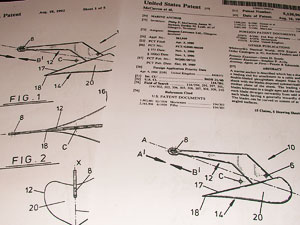

The Delta patent filed by Simpson-Lawrence includes some test data plus a number of fascinating imagined variants of the design.

Performance of the Delta in the 21st century

The Delta, per its design criteria, did deliver a significant improvement over its ancestral plow type, and jumped ahead of the Bruce to become the best anchor at the time of its release (with the possible exception of the then relatively unknown Bügel). In the history of anchor development, it occupies a nether region between the old and new generation types, certainly superior to all former patterns, but still far from the ultimate general purpose anchor.

Like the articulated CQR, the convex plow holds poorly in soft mud and dislikes weed and grass (these are key areas where the Rocna for example is drastically superior). These difficult bottoms, very hard compact sand, grass, weed, kelp, and others, are where the Delta is found wanting. This is confirmed by comparison testing and feedback from those boaters with comparative experience.

Compared to the new

The following summary comments (complete and verbatim) from West Marine relating to their 2006 anchor comparison testing are referred to in order to exemplify the differences between the Delta and the Rocna:

- Delta 35 (36 lb):

- “Variable results ranging from around 1,500lb. to 4,500lb. Drags at limit.”

- Rocna 15 (32 lb):

- “Superb, consistent performance. Held a minimum of 4,500lb and engaged immediately.”

The following efficiency ratings (holding capacity vs measured mass) from John Knox’s test published by Practical Boat Owner in August 2011 reiterate the truly drastic differences that are apparent in controlled testing:

- Delta 35 kg (36 lb):

- 11

- Rocna 15 (35.7 lb):

- 30

Finally, the Delta is classified as HHP (High Holding Power) by Lloyd’s Register. The Rocna is classified as SHHP (Super HHP), a higher standard which requires the anchor to resist pulls at least 200% that of a HHP anchor, over three different seabeds.

Peter has written some commentary on the Delta which is published here in closing.

Peter Smith on the Delta anchor

“I have owned and put some 20,000 NM (on a voyage from England to New Zealand) on a 40 kg / 88 lb original Delta. It was this voyage and the problems experienced – such as dragging in the soft mud of the Chesapeake and New Zealand rivers, the grassy bottoms in New Zealand’s lower South Island, difficulty getting a set on the thin coral layer in the Bahamas, problems with swinging room in the crowded anchorages of Rhode Island and Maine, and disconcerting events such as the boat not being where we left it because the wind changed direction! – all led to the development of a new generation anchor.

“The original Delta versions were very well built, with nice detailing such as the bottom edge of the shank which had a milled V section to reduce resistance to the anchor burying. However, Simpson-Lawrence now comes under the Lewmar umbrella, and the quality of current anchors which I have seen are nothing like the original production models. No shank bevel, all steel edges are sharp with no pre-galvanizing chamfers, and no cleaning of intermittently rough galvanizing.

“Further: the shank design has a straight neck with no gusset were it joins the blade, and therefore the anchor just sits on the bow roller where it tends to wobble and even jump in a seaway, with no way to restrain it other than a lashing or pin. This design element has also proven to be a major design weakness. The shank, heel, and cast toe are welded together with all three components meeting at a critical apex. The shank is only in effect welded to the heel which is in turn welded to the toe. I have personally seen three anchors which have broken at this junction. (With the Rocna, I designed a gusset into the equivalent neck point, spreading the shank loads down into the heavy plate toe where it acts as a reinforcing beam across the toe-to-heel joint. At the same time, the gusset forms the shape required to lock the anchor into the bow roller preventing vertical movement when in a seaway.)

“The design uses the tip-weight to roll the anchor around the curved heel plate edges into the setting position. This turning moment is critical to the anchor’s performance and yet is observed to be marginal at best, only just rolling the anchor on a flat concrete floor. The heel blade edges settling into soft mud or a build-up of mud etc on the shank surfaces would explain a failure to set, especially in a re-set situation. The Delta has a disturbing tendency to come free on a severe veer (90° or greater) and worse still, often will not re-set, especially if dragged at any pace by a boat in any degree of wind.

“(The Rocna on the other hand has a very positive righting moment created by the heavy toe which rotates the anchor around the roll-bar, the supporting skids, and the shank end. With careful design and weight cut where it’s not required, and putting it where it is needed, ~33% of a Rocna’s weight rests on the tip where it is most effective. Also, one feature of the Rocna is its ability to stay set after a 90° or 180° veer, and to re-set immediately if dislodged for any reason. The design is made to be roll-stable; i.e. it will remain embedded if dragged beyond yield and will not surface or hop out as the Delta is prone to once dragging.)

“Due to the plow shape and relatively low projected area for anchor weight, the Delta’s holding power in soft mud or any semi-fluid medium is little better than its predecessors.

“The Delta’s setting performance is reasonable in soft mediums but the cast tip is relatively blunt, without the ‘chisel’ cutting tip characteristic of for example a Rocna, meaning that setting performance drops off dramatically in more difficult material, and will not work at all in weed and grass mat. On the other hand, it is in these more difficult areas of soft semi-fluid mediums, coral rubble, weed mat and kelp, that the Rocna with its quick set high hold characteristics has developed its enviable reputation.”

— Peter Smith, SV Kiwi Roa New Zealand

References

- “The Holding Power of Anchors” G. I. Taylor, The Yachting Monthly and Motor Boating Magazine April 1934

- US Patent 1,974,933 “Anchor” [CQR] G. I. Taylor, USPTO September 1934

- US Patent 2,576,390 “Anchor” [Danforth] R. S. Danforth, USPTO November 1951

- US Patent Des 230,518 “Anchor” [Bruce] Peter Bruce, USPTO February 1974

- US Patent 5,138,967 “Marine Anchor” [Delta] McCarron Stewart & Lyall / Simpson-Lawrence Ltd, USPTO August 1992

- « Comparatif : 20 ancres au banc d’essai » Antoine Sézérat, Voiles et Voiliers May 2003

- “Holding Power” Bill Springer, SAIL October 2006

- “Anchoring in the Modern World” Colin Speedie, Attainable Adventure Cruising March 2008

- “Anchors Aware! Anchors On Test” Professor John Knox Practical Boat Owner August 2011